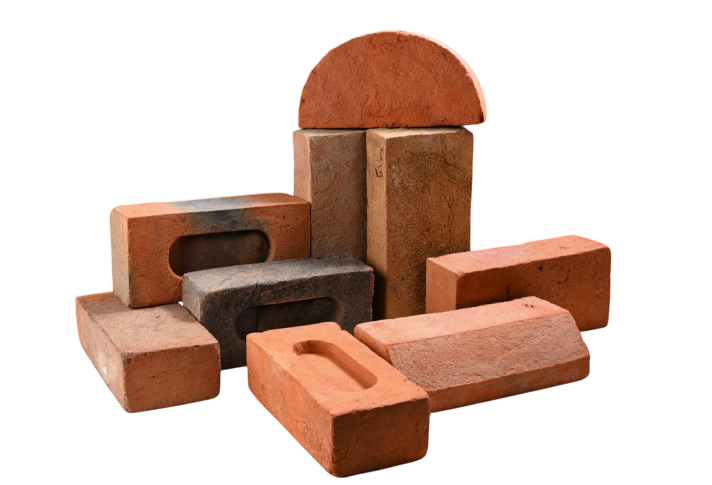

RAM BRICKS INDUSTRIES specializes in the production of eco-friendly fly ash bricks using a semi-automated hydraulic press system. These bricks are created from a mixture of clay, sand, cement, and lime, compacted for high durability and structural strength. The bricks are cured over 14–21 days through controlled water or steam methods to enhance their strength, making them a reliable alternative to traditional clay bricks.

What sets these bricks apart is their environmental sustainability—they repurpose industrial byproducts like fly ash, reducing landfill waste and carbon emissions associated with red clay brick production. These bricks comply with national building norms, are more uniform in size, and offer higher compressive strength and thermal insulation. RAM BRICKS focuses on quality assurance, with each batch tested for accuracy, strength, and finish. The approach not only contributes to green construction but also aligns with governmental programs like PMAY and Smart Cities.

This service is ideal for residential, commercial, and infrastructure projects seeking long-term value, cost-effectiveness, and sustainable building practices. As the demand for green construction rises, RAM BRICKS stands at the forefront, offering a modern solution that meets both regulatory standards and environmental goals.

— Our Service

Made from industrial waste (fly ash), promoting recycling.

High compressive strength and thermal insulation.

Uniform dimensions and smooth finish.

Reduced construction cost and time.

Compliant with BIS and eco-construction norms.

Long-lasting, weather-resistant material.

Minimal environmental footprint.

Suitable for a variety of construction applications.

Your Vision, Our Creation | Building Sustainable Tomorrow, Brick by Brick